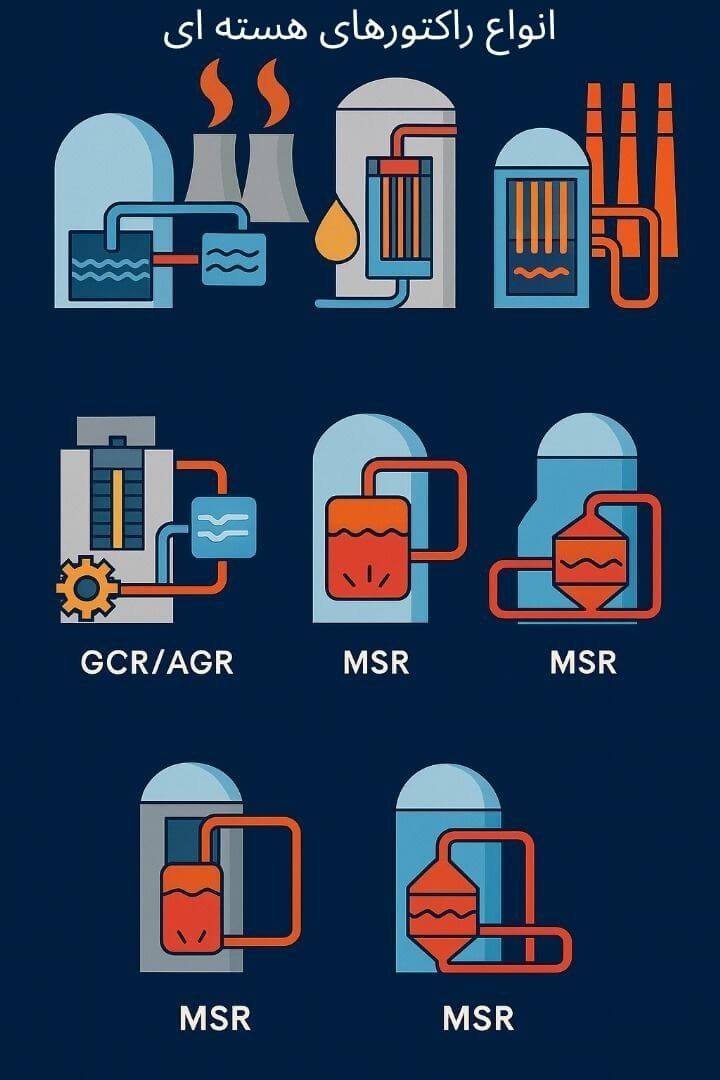

Types of Nuclear Reactors

Nuclear reactors, as vital systems in nuclear power plants, convert the energy released from nuclear fission into thermal energy. This thermal energy is then converted into electrical energy by steam turbines. This article provides a specialized, comprehensive analysis of different types of nuclear reactors, examining the technical features, advantages, and disadvantages of each, and explaining their role in global energy supply.

1) Light Water Reactors (LWRs)

Light water reactors are among the most common types of nuclear reactors and are divided into two main categories: Pressurized Water Reactor (PWR) and Boiling Water Reactor (BWR). In both types, light water (H2O) is used as a coolant and neutron moderator.

Pressurized Water Reactor (PWR):

Technical operation: In these reactors, water flows in a closed loop under high pressure (typically around 150 to 160 atmospheres) to prevent boiling. The hot water is then directed to a steam generator, where steam is produced to drive steam turbines and generate electricity.

Technical advantages: The complex, multi-layer design of these reactors provides high safety under various operating conditions. For this reason, PWRs are used in most nuclear power plants worldwide.

Challenges: Advanced technical maintenance and the need for sophisticated support systems to control pressure and temperature are among the challenges of this reactor type.

Boiling Water Reactor (BWR):

Technical operation: In BWRs, water boils directly in the reactor core, and the produced steam is sent straight to the steam turbines. This design is simpler and has one less energy conversion stage.

Technical advantages: The power generation process is more efficient due to the direct conversion of water to steam, and the need for a separate steam generator is eliminated.

Challenges: More precise and stringent control over nuclear reactions and management of various operating conditions are key requirements for this reactor.

2) Heavy Water Reactors (HWRs) or CANDU

Heavy water reactors, known as CANDU (Canada Deuterium Uranium), use heavy water (D2O) as both coolant and neutron moderator.

Technical operation: Due to its effective neutron moderation, heavy water allows the use of natural uranium (U-238) without the need for enrichment. Fuel in these reactors is placed in fuel channels, and heavy water circulates around them.

Technical advantages: Using natural uranium as fuel reduces fuel costs. In addition, these reactors can be refueled online (during operation), adding to their efficiency and flexibility.

Challenges: The production and maintenance costs of heavy water are high, and advanced equipment is required to manage it.

3) Breeder Reactors

Breeder reactors are specifically designed to produce more nuclear fuel than they consume. These reactors can use uranium-238 or thorium as initial fuel and, through nuclear processes, produce plutonium-239 or uranium-233.

Technical operation: These reactors use fast neutrons to carry out fission reactions. Because of this feature, they can convert fertile materials into new fissile fuel.

Technical advantages: They have very high efficiency in utilizing nuclear resources and can produce additional fissile material, which can significantly reduce the need for fresh uranium mining.

Challenges: Complex design and the need for advanced technology to control and manage nuclear processes are among the challenges of this type of reactor. Additionally, they must be carefully managed to prevent the production of hazardous radioactive waste.

4) Gas-Cooled Reactors (GCRs and AGRs)

Gas-cooled reactors use carbon dioxide gas as the coolant and graphite as the neutron moderator.

Gas-Cooled Reactor (GCR):

Technical operation: In this type of reactor, carbon dioxide gas is used as a coolant to transfer heat from the reactor core to the steam generator, while graphite acts as a moderator to slow down neutrons.

Technical advantages: The use of natural uranium fuel reduces costs and enables simpler systems for operation.

Challenges: Lower efficiency and the need for precise thermal management to avoid operational issues.

Advanced Gas-cooled Reactor (AGR):

Technical operation: AGR is an advanced version of GCR that uses enriched uranium fuel and, with higher operating temperatures, increases thermal efficiency.

Technical advantages: High efficiency and reduced radioactive waste due to higher operating temperatures.

Challenges: Requires advanced technology for temperature and pressure control as well as meticulous maintenance of complex systems.

5) Fast Neutron Reactors

Fast neutron reactors use fast neutrons to carry out fission reactions and do not require a moderator.

Technical operation: These reactors can directly use fast neutrons in fission reactions, which increases fuel utilization efficiency. They can also operate as breeder reactors.

Technical advantages: Significant reduction of radioactive waste and increased fuel efficiency. They also allow the use of less common nuclear resources.

Challenges: Complex technology and the need for precise management of nuclear processes to ensure safe and stable reactor operation.

6) Molten Salt Reactors (MSRs)

Molten salt reactors are an advanced type of reactor that use nuclear fuel in the form of molten salts at very high temperatures.

Technical operation: In these reactors, the nuclear fuel circulates as a liquid at high temperatures within the reactor system, and the fission process and energy production occur simultaneously.

Technical advantages: Very high efficiency, greater inherent safety due to the liquid nature of the fuel, and the ability to use various types of nuclear fuel, including uranium and thorium.

Challenges: Design complexity and the need for materials resistant to high temperature and corrosion. Advanced management systems are also required for control and maintenance.

Customs clearance of specific goods is possible upon obtaining the necessary special permits.

Frequently Asked Questions

What is the key difference between PWR and BWR?

In a PWR, pressurized water in a closed loop does not boil and steam is generated in a steam generator; in a BWR, water boils in the reactor core and the steam goes directly to the turbine.

What advantage does CANDU have over light water?

Use of natural uranium and the ability to refuel during operation; however, heavy water production/maintenance costs are higher.

What challenges do molten salt reactors face?

Complex design, the need for materials resistant to high temperature/corrosion, and advanced systems for management and maintenance.

.png)