Customs Clearance of Plastic Injection & Manufacturing Machinery in Iran (HS Code + Documents & Permits)

Plastic injection and manufacturing machines are essential industrial equipment for mass production of plastic parts and products across automotive, packaging, home appliances, electronics, and medical device sectors. With rising domestic demand, imports of these machines into Iran have grown—and accordingly, their customs clearance requires care, complete documentation, and familiarity with relevant standards and permits.

For time and cost estimates to clear plastic injection & manufacturing machines, contact the Saba Tarkhis experts.

Instant Free Consultation

1) Detailed Description of Plastic Injection & Manufacturing Machines

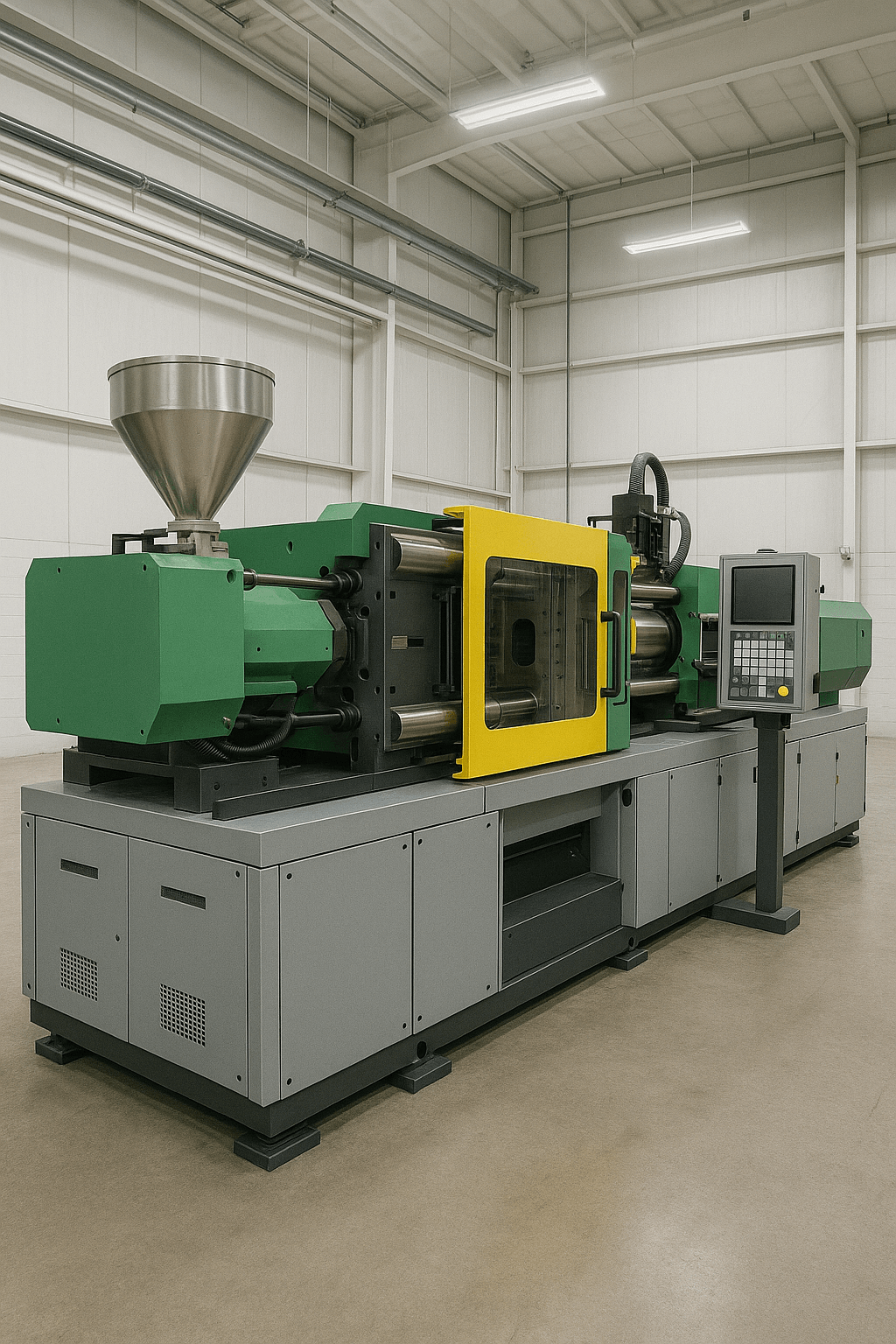

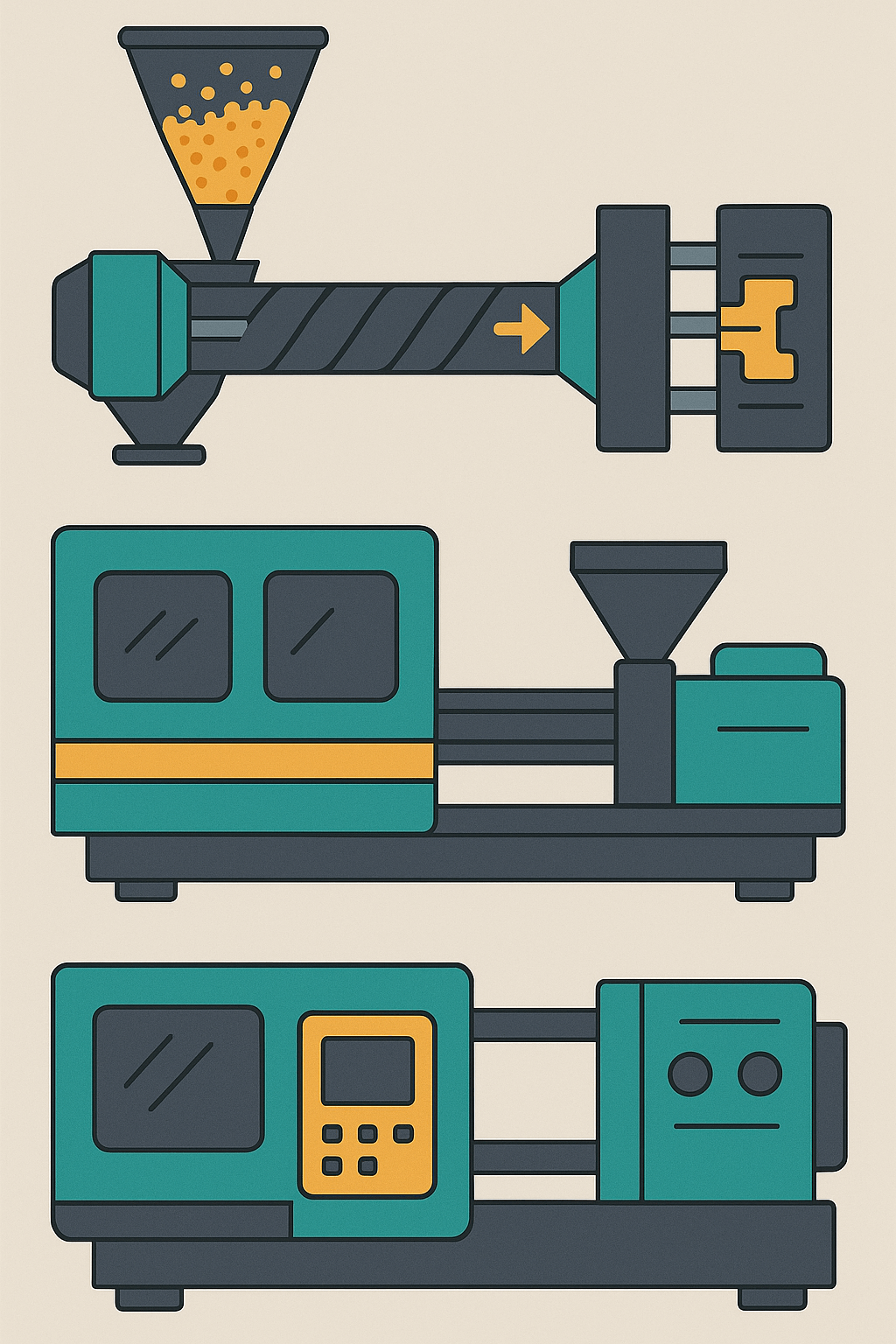

Plastic injection machines melt polymer feedstock (typically granules) and inject it in a controlled manner into a mold, enabling production of complex parts with high dimensional accuracy. Tight control of temperature, pressure, and injection speed ensures surface quality, uniform strength, and repeatability—making these machines the backbone of many industrial production lines.

Key components include: the injection unit (screw/barrel and nozzle for melting and conveying the melt), the clamping unit to lock the mold and withstand injection pressure, the mold (defining the part’s final geometry, usually made from tool steel), and the control system that monitors parameters and sequences the cycle for consistent output. Machines are supplied in various capacities (clamp tonnage, shot volume) for materials such as PE, PP, PA (nylon), and more.

Proper machine sizing, sound mold design, and precise process settings directly affect quality, scrap rate, and line productivity.

2) Types & Applications

3) Key Points for Clearance

Clearing industrial machinery—including plastic injection and manufacturing machines—is a sensitive, multi-step process requiring precise knowledge of customs law and adherence to international standards. Key considerations include:

Tariff & HS Code: Injection and plastic manufacturing machines are classified under HS Code 847710. Correct classification not only sets duties and taxes but also speeds accurate clearance. Misclassification can cause delays and extra costs.

Technical documentation: Submit full, valid technical docs—drawings, detailed specifications, and catalogs—clearly proving compliance with national and international standards. Drawings should include dimensions, weight, power, and other specs essential to customs assessment and approval.

Standards certificates: Many imports require international certifications such as CE (EU compliance) and ISO. These indicate the machines meet safety, quality, and performance requirements. Lack of such certificates may lead to rejection or delays; check any destination-specific national standards in advance.

Duties & taxes: Duties are calculated on CIF value and the applicable tariff rate. Accurate calculation and timely payment prevent delays. Keep an eye on policy or tariff changes that may affect costs.

Special permits: Depending on type and application, permits from authorities such as the Ministry of Industry, Mine & Trade (MIMT) or the Department of Environment may be required—especially if there are notable environmental impacts or special chemicals. Obtain these before clearance to avoid delays.

Customs facilitations: Some importers may qualify for exemptions/reductions—e.g., for production line upgrades. Knowing eligibility and procedure can cut costs; expect extra documentation and admin follow-up.

4) Tariff & HS Code

Plastic injection machines fall under HS Code 847710 (machinery for working plastics and producing finished products). Correct classification determines duties, taxes, and import requirements.

| Item | Short Description | HS Code |

|---|---|---|

| Plastic injection machines | Granule-to-part in mold; mass production | 847710 |

Final line item may vary by function, power, auxiliaries, and line configuration.

5) Special Import & Export Conditions

Import

Compliance with international standards (CE/ISO) and submission of technical documents are mandatory. Depending on type and environmental impact, permits from competent bodies (e.g., MIMT, and if needed the Department of Environment) are required. Accurate sworn translations and full consistency across documents (Invoice, B/L, Packing List) speed up clearance.

Export

Exports from Iran are more limited, mostly to neighboring and developing countries. Know destination standards and provide valid technical documentation.

6) Iran Market

Main origins for Iran: Germany, Japan, China, Italy, and South Korea—valued for high quality, advanced technology, and wide capacities. Iran is a notable regional importer; domestic demand is rising with industrial development.

Export destinations from Iran (limited): neighboring markets such as Iraq and Afghanistan.

7) Trade Volume

As downstream polymer industries expand, imports of injection machines have grown. Each year, a significant number of machines worth millions of USD are imported—supporting line upgrades and quality improvements.

8) Global Market

Leading exporters: Germany and Italy (advanced tech, top quality), China (variety and competitive pricing), Japan and South Korea (precision and reliability). Major importers include industrial economies and countries rapidly expanding packaging and automotive sectors.

9) Documents Required for Clearance

- Commercial Invoice

- Bill of Lading & Packing List

- Catalogs/drawings/specs & standards certificates (CE/ISO)

- Certificate of Origin

- Import permits as applicable (MIMT and, if required, Environment)

- Customs declaration and cargo insurance

For precise HS 847710 classification, exemption checks, and document prep, lean on the Saba Tarkhis team.

Request a Pro-FormaKey Tips & Practical Advice

- Ensure full alignment of data across all documents (technical description, quantities, value, weights)

- Pre-check applicable standards and permits to avoid customs holds

- Assess eligibility for incentives/exemptions for production line upgrades

- Plan transport, insurance, and post-clearance installation/commissioning timeline

FAQs

What is the HS Code for injection machines?

Primarily 847710; the final line item depends on technical specs/configuration.

Which documents are needed for clearance?

Invoice, B/L, Packing List, catalogs/drawings/specs, standard certificates (CE/ISO), CO, and applicable import permits.

Are customs incentives or exemptions available?

In certain programs for production-line modernization, eligibility may exist depending on conditions and documentation.

Premium Customs Services by Saba Brokerage

With extensive experience in customs clearance, Saba Brokerage offers comprehensive, specialized services for industrial machinery—especially plastic injection & manufacturing equipment:

Specialized consulting: Advice on selecting suitable machines, navigating import/clearance regulations, and leveraging customs incentives.

Streamlined clearance: Veteran specialists manage the process quickly and seamlessly—minimizing time and cost.

Administrative handling & documentation: We prepare technical files, obtain required permits, and submit complete documentation to customs.

Continuous follow-up: From port arrival to final release and delivery, we track progress and keep you informed—avoiding delays.

Insurance & risk coverage: Appropriate insurance for transport and clearance phases protects against potential losses.

Post-clearance support: Guidance on installation/commissioning and ongoing technical support ensures optimal use of imported equipment.

Choose Saba Brokerage for a stress-free, efficient import and clearance experience—focused on speed, safety, and optimization.

.png)