Customs Clearance of Industrial Valves and Parts from Iranian Customs (HS Code + Documents & Permits)

Industrial valves play a crucial and strategic role in many sectors by controlling and directing the flow of liquids, gases, and chemicals. These devices are used across oil & gas, petrochemicals, water & wastewater, power plants, food, and pharmaceuticals. They are engineered to operate reliably under harsh conditions and high pressures.

For an estimate of time and cost for industrial valve clearance (Ball/Butterfly/Gate/Needle/Safety), contact the Saba Tarkhis experts.

Instant free consultation1) Types of Industrial Valves and Their Applications

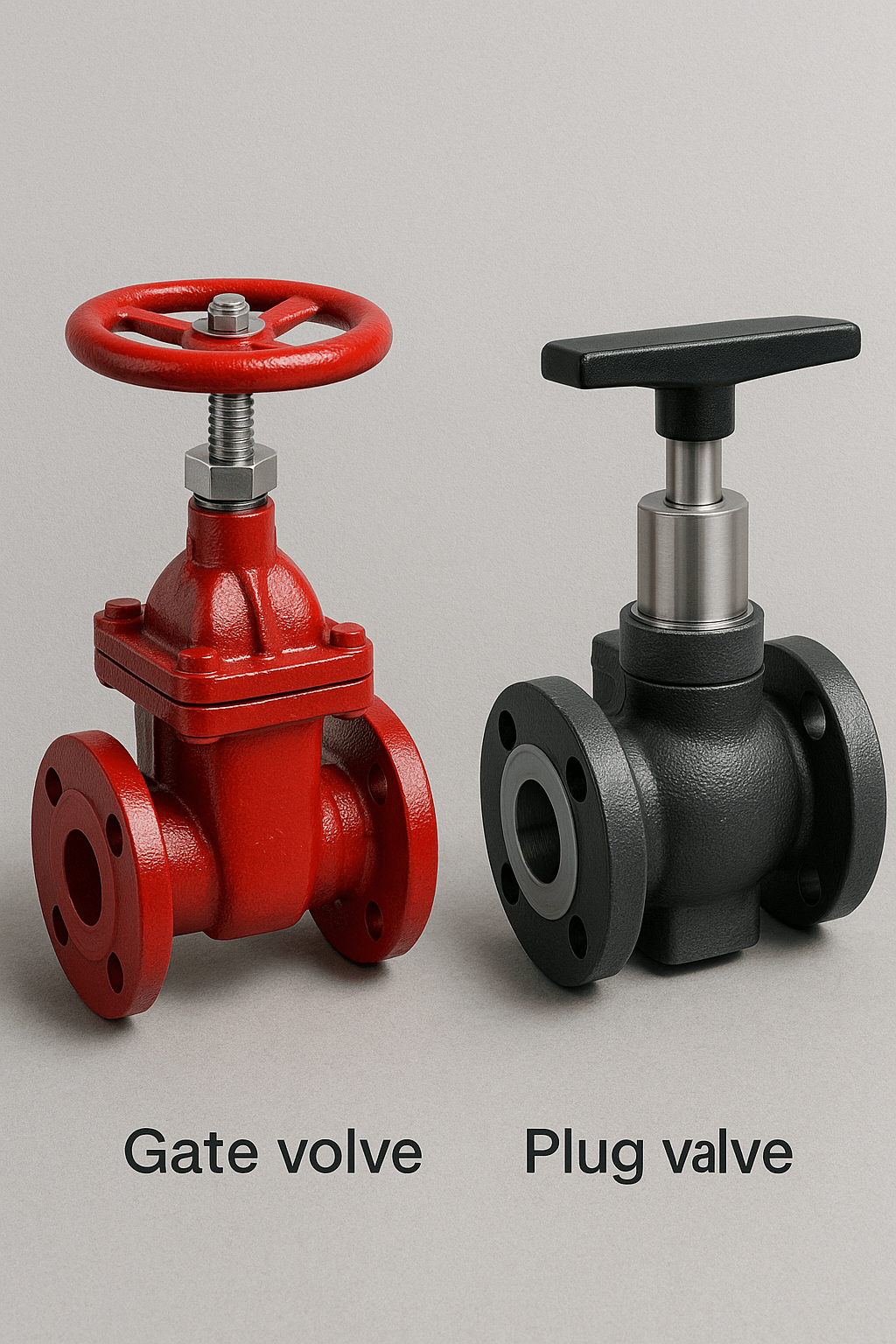

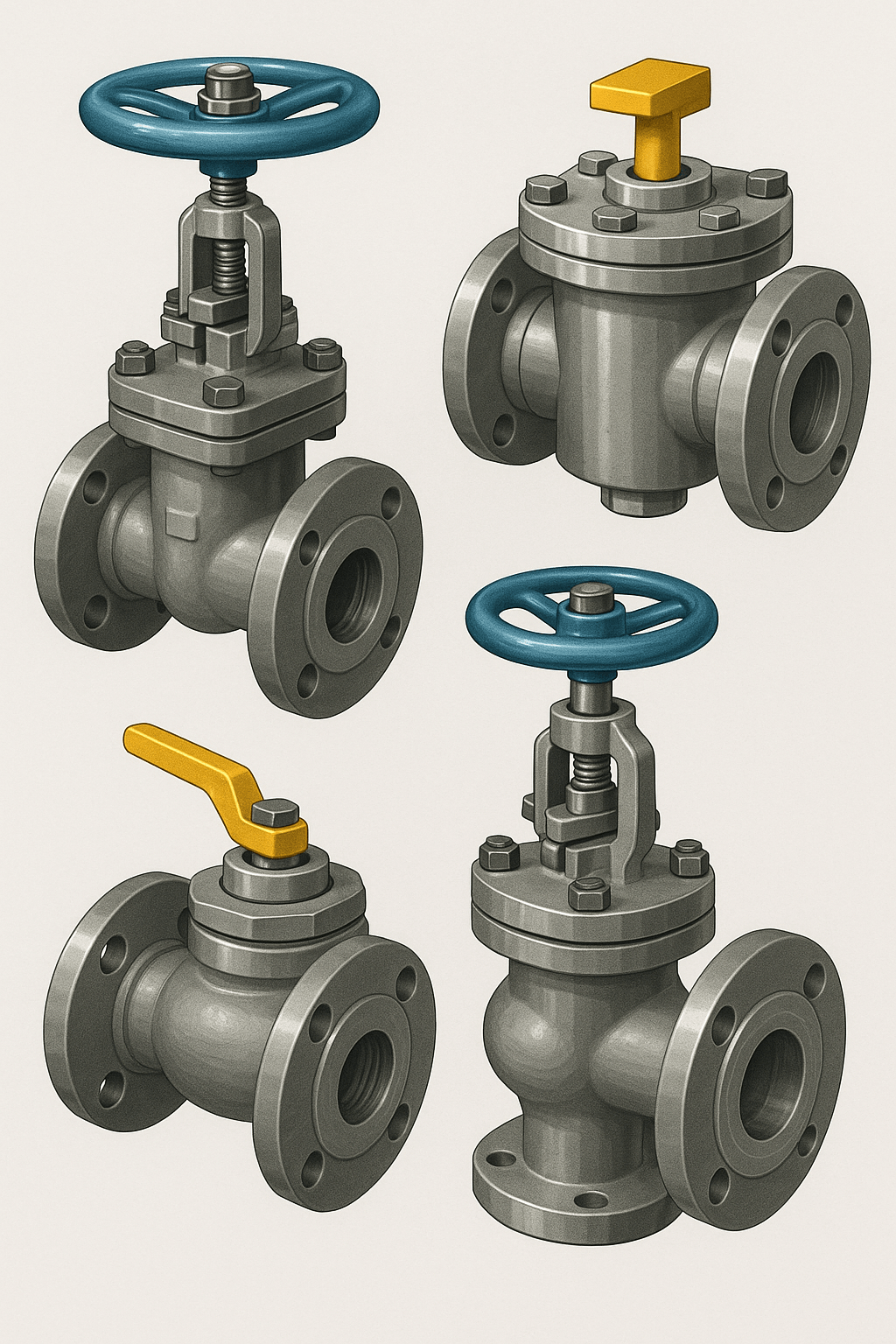

1. Ball Valves

Simple and effective operation: rotating the ball opens or shuts the flow completely.

Suitable for quick shutoff: the straightforward design enables rapid opening and closing.

Broad use in corrosive environments: can be manufactured from corrosion-resistant materials, making them suitable for chemical industries.

2. Butterfly Valves

Lightweight and compact: ideal where smaller, lighter equipment is required.

Ease of use: fast opening/closing and simple flow control.

Versatile: usable across a wide temperature range in different industrial settings.

3. Gate Valves

Simple, robust structure: flow is controlled by a vertically moving gate without obstructions.

Suited to high pressure: resistant to severe pressures for pressurized transfer systems.

Not for throttling: primarily intended for full shutoff or full open, not precise regulation.

4. Needle Valves

High precision control: their design enables very accurate flow adjustments.

Use in sensitive industries: suitable for chemical dosing and sensitive process control.

Operable at various temperatures and pressures: can be used in different conditions.

5. Safety Valves

Protect equipment and personnel: relieve excess pressure to prevent explosions and damage.

Automatic, safe operation: activate automatically in emergencies to keep pressure safe.

Use in critical environments: widely used in power plants and chemical industries.

2) Key Points in Industrial Valve Customs Clearance

Importance of the HS (Harmonized System) Code

| Product | Short description | HS Code |

|---|---|---|

| Industrial valves and components/parts | Control/direct the flow of liquids and gases | 8481 |

Exact classification depends on type, body material/alloy, working pressure, nominal diameter, and application.

Required Documents for Clearing Industrial Valves

Proforma Invoice and Commercial Invoice: contain full information on product type, quantity, price, shipping, and payment terms.

Cargo insurance policy: ensures compensation in case of any incidents during international transport.

Certificate of Origin: issued by the chamber of commerce in the exporting country, confirming the goods’ origin.

Specialized permits: depending on the valve type and destination country, you may need approvals from authorities such as the Ministry of Oil, Ministry of Industry, Mine & Trade, or the National Standards Organization.

Customs Declaration: must be completed accurately with detailed information about the goods and import conditions.

3) Standards, Requirements, and Special Conditions for Import/Export

Manufacturing and exporting industrial valves require advanced technology and technical complexity, so they are mainly produced in industrialized, developed countries. Key exporters include:

China: the largest producer and exporter, focused on mass production and low cost.

Germany: a leading exporter emphasizing high quality and precise engineering.

Italy: renowned for advanced designs and innovative technologies.

USA: producer of a wide range of valves with state-of-the-art technology and superior quality.

Main importing countries of industrial valves

Due to broad industrial and infrastructure needs, many developing and developed countries import valves. Major importers include:

Iran: requires extensive valve imports for large industrial and infrastructure projects.

India: a fast-growing developing economy with high industrial growth.

Saudi Arabia: a major importer due to its focus on oil & gas industries.

Russia: needs robust equipment for harsh climates and military applications.

Need HS 8481 classification, API/ISO approvals, and document preparation? Our team manages the process end-to-end.

Submit proforma request4) Exporting/Importing Countries and Trade Volume

Main Exporters and Importers of Industrial Valves

Manufacture and export of industrial valves, due to technical complexity and need for advanced technology, are largely centered in industrialized nations. Major exporters include:

China: the largest producer and exporter, focused on mass production and low cost.

Germany: a top exporter known for high quality and precise engineering.

Italy: famous for advanced designs and innovative technologies.

USA: producer of various industrial valves with cutting-edge technology and top quality.

Owing to broad industrial and infrastructure demands, many developing and developed countries import valves. Major importers include:

Iran: requires extensive imports for large industrial and infrastructure projects.

India: a developing nation with high industrial growth.

Saudi Arabia: a major importer due to its oil & gas focus.

Russia: requires equipment resistant to harsh climates and for military uses.

Import and Export Volumes of Industrial Valves in Iran

Frequently Asked Questions

What is the HS Code for industrial valves?

According to your text, industrial valves are classified under 8481; final determination depends on type, materials, working pressure, and application.

Which approvals are required for imports?

As applicable: API/ISO certifications, approvals from the Institute of Standards & Industrial Research of Iran, and other specialized permits (Oil Ministry, MIMT, Atomic Energy Organization).

Which documents are mandatory for clearance?

Proforma and commercial invoices, transport insurance, certificate of origin, specialized permits, and a duly completed customs declaration.

Special Customs Services by Saba Brokerage

As one of the most reputable and experienced customs brokers, Saba Brokerage offers specialized services to facilitate and accelerate the customs clearance of industrial valves. These comprehensive services are designed with all aspects of customs procedures in mind to best meet importers’ needs. They include:

Pre-clearance expert consulting: our seasoned experts guide you in choosing the correct tariff line, preparing the required documents, and obtaining necessary permits ensuring every stage complies with legal requirements and international standards.

Preparation and completion of customs paperwork: our professional team, fully versed in customs rules and regulations, prepares and completes all documents precisely, preventing issues and delays and speeding up clearance.

Permit follow-ups: some valve types, due to technical sensitivities, require special permits from relevant organizations. Leveraging experience, we obtain these approvals quickly and accurately.

Fast and efficient clearance: with full familiarity with customs regulations and process management, our experts can clear your industrial valves in the shortest possible time, ensuring a smooth, highly efficient process.

Post-clearance services: even after clearance, we remain by your side with services such as prompt delivery and follow-up on post-clearance issues, ensuring everything concludes to your complete satisfaction.

With these comprehensive services, you can achieve a fast, reliable, and economical clearance process for your industrial valves and benefit fully from customs solutions.

.png)