Customs Clearance of Ball Bearings & Roller Bearings in Iran (HS Code + Documents & Permits)

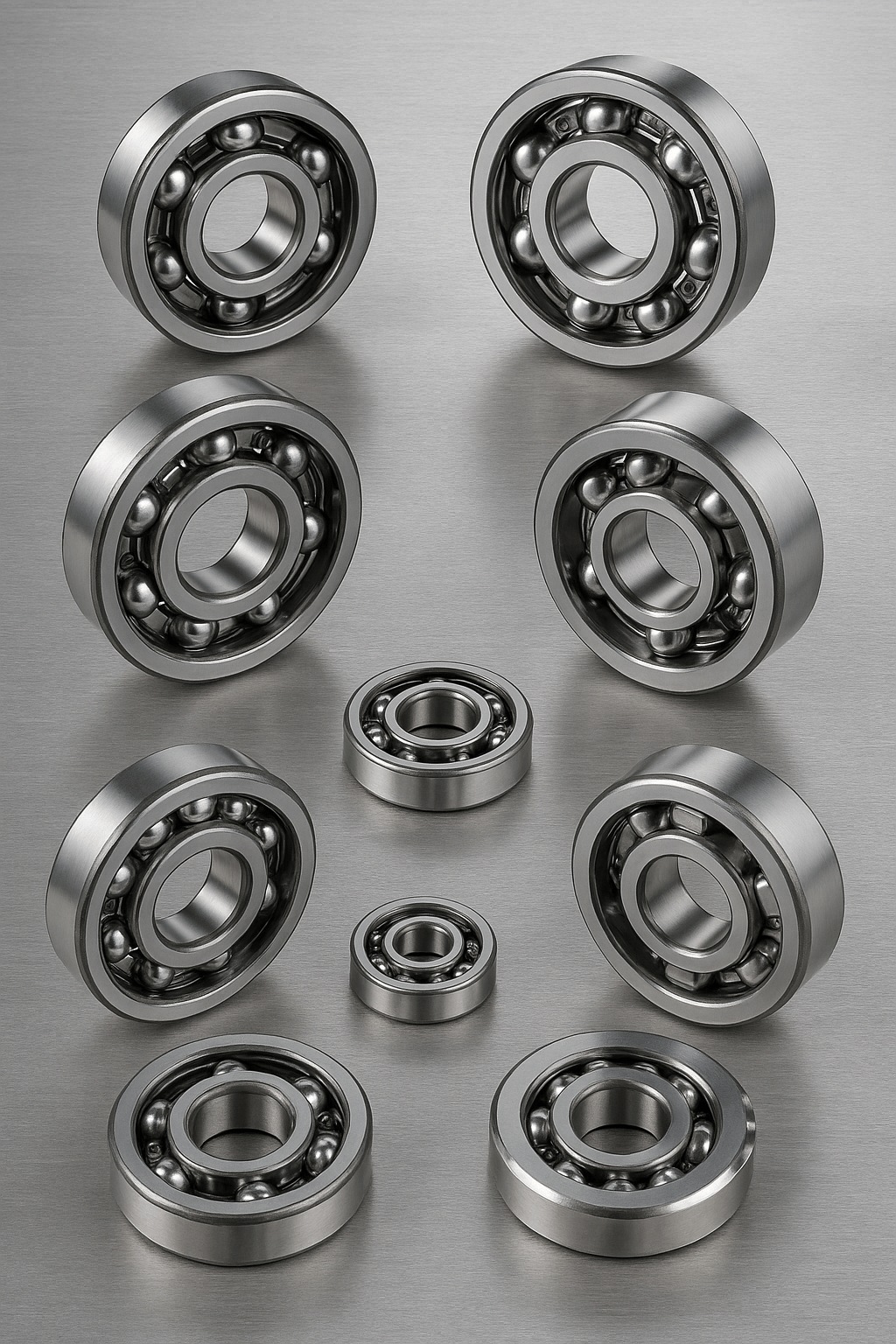

Ball bearings and roller bearings are critical components in mechanical and industrial assemblies that ensure proper and optimal performance of various equipment. By reducing friction and distributing loads appropriately, these parts help increase the service life and efficiency of industrial equipment. Ball and roller bearings are used across a wide range of industries, including automotive, oil & gas, steel, mining, petrochemicals, and even household appliances. Due to the broad industrial demand for these parts and their importance in maintaining machine performance, the import and customs clearance process for these products is highly vital and sensitive.

To estimate the time and cost of bearing and roller bearing clearance, contact the Saba Tarkhis experts.

Instant Free Consultation1) Types of Ball Bearings & Roller Bearings and Their Applications

Ball Bearings

Thanks to their simple design and high efficiency, these bearings are the most widely used across industries. Deep groove ball bearings can carry both radial and axial loads; therefore, they are used in equipment such as electric motors, pumps, gearboxes, compressors, and even agricultural machinery. With high-speed capability and low maintenance needs, they are suitable for general and specialized applications.

Designed to compensate for misalignment, these are ideal where shaft deflection or variable loads exist. They are mainly used in long-shaft equipment, textile machinery, and power transmission systems that require automatic alignment and combined load capacity. Self-alignment prevents issues caused by misalignment and extends equipment life.

Roller Bearings

Engineered for heavy radial loads and capable of high speeds. Because of their design, they’re used where high load capacity and stable performance are required, such as mining equipment, industrial mills, and heavy machinery. Their simple structure and heavy-load capacity make them ideal for industrial use.

Thanks to their geometry, they can carry radial and axial loads simultaneously. This makes them common in power transmission systems, automotive axles, gearboxes, and industrial machines with complex loading. Depending on type and contact angle, they serve a variety of loading conditions.

Designed for heavy radial and axial loads in harsh and contaminated environments. Common in industrial presses, mills, and heavy equipment that face combined loads under unstable conditions. They also compensate for minor shaft misalignments critical in heavy industrial applications.

2) Importance of Proper Bearing Selection

3) Specialized Applications of Bearings in Industries

4) Customs Tariff (HS Code) and Import Regulations

| Item | HS Code | Short Description |

|---|---|---|

| Ball Bearings | 84821000 | Deep groove and related types for general/special uses |

| Roller Bearings | 84822000 | Cylindrical, tapered, spherical; heavy radial/axial loads |

Final classification depends on cage type, sealing, internal clearance, ring material, and end use.

Need precise HS classification, permits, and document preparation? Our team manages the entire case end-to-end.

Submit Proforma Request5) Documents and Legal Requirements for Bearing Clearance

-

Proforma Invoice: Details the order item type, quantity, unit price, payment terms, and delivery time. Acts as a preliminary contract between seller and buyer and is required for customs clearance. Accuracy of the information is critical.

-

Packing List: Specifies packaging details such as number and type of packages, net/gross weight, dimensions, and contents of each package. Essential for inspection and matching with customs documents.

-

Certificate of Origin: Indicates the producing country. Issued by the Chamber of Commerce or other competent bodies. Helps customs apply proper tariffs and, in some cases, allows preferential rates under trade agreements.

-

Certificate of Conformity: Confirms bearings are produced in line with international standards such as ISO or ANSI covering quality, durability, and performance. In some countries, import without these certificates is not possible due to the critical nature of applications.

6) Standards and Quality Requirements

Defines a quality management system that ensures all production processes follow continual improvement and customer satisfaction. Importing from ISO 9001-certified manufacturers means high-quality products aligned with global standards.

ISO 14001:

Focuses on environmental management systems, ensuring bearing production processes protect the environment and reduce pollution especially important in today’s markets.

ANSI (American National Standards Institute):

ANSI standards focus on technical and performance requirements in the U.S. market. Bearings made to ANSI standards offer high quality and performance for complex and sensitive applications.

7) Special Import/Export Conditions and the Global Market

The global bearing market is driven by high demand across industries. China is the largest producer and exporter. European countries like Germany and Italy are also major exporters. The largest importers globally include the United States, India, and Brazil.

Frequently Asked Questions

What are the HS Codes for ball and roller bearings?

According to the text: ball bearings 84821000 and roller bearings 84822000. Final determination depends on type, cage material, and application.

Which standards should be met for imports?

Certificates such as ISO 9001, ISO 14001, and compliance with ANSI are recommended for quality, environment, and technical requirements.

What documents are needed for clearance?

Proforma invoice, packing list, certificate of origin, and certificate of conformity; other documents may be required depending on the case.

Special Customs Clearance Services by Saba Brokerage

With extensive experience in clearing industrial goods especially ball and roller bearings Saba Brokerage offers specialized services to clients, including:

Pre-clearance Consulting: Our experts analyze the bearing type and provide optimal strategies for fast, cost-effective clearance, including correct HS selection, document preparation, and technical recommendations to avoid issues.

End-to-end Clearance Execution: From order registration to documentation and obtaining permits, every step is handled precisely by our professional team, so you won’t worry about complex and time-consuming procedures.

Accurate & Continuous Follow-up: We closely track the process and liaise with customs officers to prevent delays and accelerate clearance crucial for on-time delivery.

Post-clearance Support: We remain at your side after clearance and provide expert assistance if any issue arises boosting peace of mind and satisfaction.

Supplier Network Advantage: With access to a global network of reputable suppliers, we can source quality parts that match your needs at the best prices reducing import costs and increasing efficiency.

.png)